21700 Battery pack automatic wire bonder/18650 Ultrasonic Wire Bonding Machine/Welding Machine For Tesla Battery

USD $35000 - $55000 /Set

Min.Order:1 Set

Quick Details View All >

Shenzhen AITOP Intelligent Equipment Co. LTD

Product Details

21700 Lithium battery pack ultrasonic aluminum wire bonding machine For 26650/32650 battery welding

Equipment basic working principle:

After the module assembly process is completed, the equipment is used to automatically load the system,

and then sent to the welding area through the automatic feeding system. The welding head system

performs ultrasonic welding according to the setted welding parameters and position. After the welding is

completed, the module is sent to the designated position automaticly by the feeding system, and the

equipment operator takes out the welded module and sends it to the next production process.

| Equipment Specifications | |

| Welding area: | 650 mm in X direction * 650 mm effective stroke in Y direction (standard) |

| Z axis: | maximum travel distance 60 mm, 1.25 μm resolution |

| Rotary axis: | ±220 degrees, 0.08 degree resolution |

| Power requirements: | 220V AC, 50/60 Hz |

| Power consumption: | 3000W |

| Compressed air: | 0.5pla |

| Display: | 17-inch color plane display |

| Working surface height: | 1150 mm from the ground |

| Occupied size: | 1300 mm long; 1300 mm wide: 1650 mm high (without warning lights) |

| Net weight: | 500 kg |

| Heavy wire horn: | Rotary, standard front cutter |

| Transducer: | Standard 60KHz, other frequencies can be manufactured according to customers' requirements |

| Welding pressure: | 50-1500 grams |

| Feed wire system: | Motor control wire feeder with optical encoder |

| Lack of wire detection: | wire feeding detection |

| Maximum arc height: | 40 mm |

| Minimum wire length detection: | 2mm feed wire |

| Spool size: | 50-120 mm OD; 22-45 mm width; 10-11 mm ID |

| Image recognition: | optics/lighting |

| Visual System: | XK Image Recognition System |

| Communication: | IO communication, Ethernet communication |

Equipment application:

Mainly used for electrical connection of power battery module cell and busbar,Applicable aluminum wire diameter range is 125~500um

18650/21700 Battery pack automatic wire bonder/Ultrasonic Wire Bonding Machine/Welding Machine For Tesla Battery

After the module assembly process is completed, the equipment is used to automatically load the system,

and then sent to the welding area through the automatic feeding system. The welding head system performs ultrasonic welding

according to the setted welding parameters and position. After the welding is completed, the module is sent to the designated position automaticly

by the feeding system, and the equipment operator takes out the welded module and sends it to the next production process.

Equipment application:

Mainly used for electrical connection of power battery module cell and busbar,Applicable aluminum wire diameter range is 125~500um

Equipment Specifications

Welding area: 650 mm in X direction * 650 mm effective stroke in Y direction (standard)

Z axis: maximum travel distance 60 mm, 1.25 μm resolution

Rotary axis: ±220 degrees, 0.08 degree resolution

Power requirements: 220V AC, 50/60 Hz

Power consumption: 3000W

Compressed air: 0.5pla

Display: 17-inch color plane display

Working surface height: 1150 mm from the ground

Occupied size: 1300 mm long; 1300 mm wide: 1650 mm high (without warning lights)

Net weight: 500 kg

Heavy wire horn: Rotary, standard front cutter

Transducer: Standard 60KHz, other frequencies can be manufactured according to customers'

requirements

Welding pressure: 50----1500 grams

Feed wire system: Motor control wire feeder with optical encoder

Lack of wire detection: wire feeding detection

Maximum arc height: 40 mm

Minimum wire length detection: 2mm feed wire

Spool size: 50---120 mm OD; 22---45 mm width; 10---11 mm ID

Image recognition:/optics/lighting

Visual System: XK Image Recognition System

Communication: IO communication,

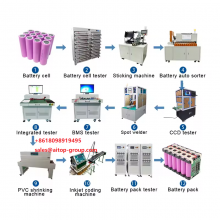

Images:

Our Company

Shenzhen Aitop Technology Co Ltd , is a manufacturer which combines R&D and marketing ,we have professional R&D team as well as proficient stuff ,and has been specializing in researching and producing high quality lithium battery machine for 10 years . Our main products ranges from 18650 battery pack assembly machine ,Power Battery PACK assembly machines ,Power Bank Assembly machine,Mobile Phone Battery assembly Machines,Battery safety test equipment,Injection molding machine,Molds, Molding materials, machine parts, etc

We keep in place with the word ,we adopt lastest technology and design ,our Aitop series battery machine stands out in the same industry area ,they are of national advanced technologycal level and have been identified by experts from Shenzhen Science & Technology and Information Bureau .Up to now ,we have obtained many inventions patents ,practical new patents ,and own independent intellectual property rights

.

With the increasing development ,We have created two workshops to manufacture battery machines and injection molding machines

Through our efforts, the Automatic Battery PACK Assembly machines are now widely used in Mobile phone,Power bank,Laptop,Electric bikes,Electric vehicle,solar street lights,Solar energy storage,Banks,LED devices,Health Equipments ect,the low-pressure injection molding machines are now widely used in PCBs, sensor products, wiring harnesses, medical electronic products, etc. In addition, OEM/ODM services can be provided to customers worldwide. Our products enjoy high quality and guarantee all-weather after-sales service, thus winning our 70% market share.we look forward to cooperation with the customers all over the world .

Contact us :

Shenzhen AITOP Intelligent Equipment Co. LTD

Sales Manager

Phone/Whatsapp/Wechat:008618520989583/008618435204981/18098989643/+8618820281861

Email:sales(@)

FAQ

1 , What is the product ?

It is an automating welding machine for 18650 ,26650 battery , use for 18650 26650 welding .

2 , how is it performance ?

It is automating , more effectioncy , it can replace 10-15 staffs works ,it can help you increase production run ,and decrease production cost .

3 , what about the quality guarantee and after-sale service ?

we provide one year quality guarantee , full time after-sale service .

4 , we want to open an automating system for lithium battery , how it can do that ?

Yes , we can provide you the battery automating system and solution .

Hot Tags: battery ir testing machine, manufacturers, suppliers, factory, customized, BMS tester,cells internal resistance tester,cells capacity tester,cells sorting machine,manual/automatic spot welding machine,battery pack integrated tester,battery pack charging&discharging cabinet wholesale, cheap, discount, quotation, low price, ,Automatic 18650 Battery Spot Welder

Contact us :

Shenzhen AITOP Intelligent Equipment Co. LTD

Sales Manager

Phone/Whatsapp/Wechat:008618520989583/008618435204981/18098989643/+8618820281861

Email:sales(@)

Contact Supplier

You May Like

New Products

Popular Searches

Recommended Products

Find Similar Products By Category