32140/32650 64ch Seperate Channel Battery Charge And Discharge Tester 18650 Battery Grading Machine

CNY 700 - 1500 /Piece

Min.Order:1 Piece

Quick Details View All >

Shenzhen AITOP Intelligent Equipment Co. LTD

5V 10A 80 Channel Prismatic Cell Tester Capacity Grading Machine Charge Discharge Machine

100V 10A charge 20A discharge battery pack testing aging machineBattery Test System

100V100a60V100v20A/30A/50A/60A Professional battery charging and discharging aging cabinet

AITOP Capacity Tester 5V100A Battery Capacity Tester battery capacity charge discharge tester

Product Details

8ch Seperate Channel Battery Charge And Discharge Tester 18650 26650 Battery Grading Machine

5v3a6a10a20a30a50a60a100a120a200a300a500a

8 Channel Seperate Channel Cell Charge and Discharge Grading and Form Machine for 18650 26650

The grading machine is divided into different types: cylinder, aluminum shell and polymer. The internal structure of them is exactly the same, but the clamps are different. The cylinder and the aluminum shell use upper and lower needles to contact, while the polymer uses a gold-plated flat clamp to clamp the tabs for punching. Different channels can be customized according to customer requirements, and the current and voltage are unified, its suitable for mass production.

Cell Grading Machine Functions

1) The graphic operation interface is used to display the voltage, current, time, capacity and other data of each battery, and the corresponding working status and abnormal conditions are displayed in various colors;

2) Battery capacity indication of any section (up to 100 segments);

3) The data points can be recorded according to the change conditions of voltage, current and time to form a complete charging and discharging curve data, and the time interval of curve data points is less than 4 seconds

4) The battery sorting function is carried out under various conditions (capacity, time, open circuit voltage, discharge platform, etc.);

5) Calculate the data of charge ratio, voltage average, discharge efficiency, etc;

6) Operator setting and operation authority;

7) It can display charge discharge curve and cycle diagram;

Cell Grading Machine Parameters

Product Description

Battery Analyzer Capacity TesterTOP-C512 18650/26650/32650 Battery Capacity Tester for 5V3A/5A 512 Channel Li-Ion Battery Charging Discharging Testing Tester BK- 3512L

Performance characteristics

Main Technical Parameters

Number of device channels | 512 (Single CPU control) |

Constant current range | 0.05 ~ 6A, resolution 1mA |

Accuracy of current measurement | ±0.1%FS

|

Sampling current accuracy | ±0.1%FS

|

Voltage measurement range | 0 ~ 5V, resolution 1mV |

Accuracy of voltage measurement | ±0.1%FS

|

Charging and discharging voltage range | Charging: 0 ~ 4.5V, discharging: 4.5 ~ 2V |

Constant voltage setting range | 3 ~4.5V |

Accuracy of constant pressure setting | ±0.1%FS

|

Time range | 0-30000 min / step, accuracy: ± 0.1% |

Heat dissipation mode | Cold wind |

Battery Clamp | Cylinder clamp, polymer clamp |

Work loop source | Temperature: 0 ~ 40 ℃, relative temperature ≤ 85% (no water condensation) |

External size | 1600mm (W) × 550mm (L) × 1840mm (H) |

Working power supply | Three phase four wire system, AC380V ± 150%, 50Hz |

Power consumption at full load | ≤9KW

|

Minimum configuration of computer system:

| 1. Dual core CPU or above, 2. 4G or above memory, 3. 500GB or above hard disk space, 4. EGA / VGA color display, one CD-ROM, one mouse 5. Windows XP or above operating system, one 6. RS232 serial communication port available. 7.The computer system shall be self configured by the user, and the number of the computer system shall be determined according to the actual needs. |

General equipment configuration and standards | 1. Appearance color of equipment, Case: silver white, Cabinet: silver white. 2. Attach the Chinese operation manual and software U disk. |

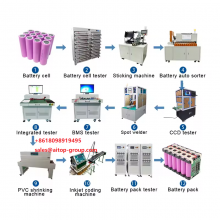

WE AITOP specialized manufacturing machine for Lithium battery assembly line (Auto pvc peeling/ paste paper /sorting/test/Welding/injection molding/Labeling/bagging Machine ) more than 10 years.

1, Our machines can do 18650/26650/32650/21700 etc ,Cylindrical batteries testing, sorting and spot welding in great speed.

2, You can design your own voltage and internal resistance.

3, We have a complete production line for power battery packs.

4, Our machines are widely used in battery factories for mobile phone, power bank, laptop , ebikes and electric vehicle .

5, We have an oversea sales office in New Delhi, India and now is quite popular.India , most battery factory machine support by us,Like intex,kites air,erd,ambrane,bmt,iccon ETC.

Any chance you like our products, please feel free to contact us.

We can provide you a perfect solution for power battery packs production!Such as attached Solutions.

we have strict quality control system and high efficiency work team and received a high evaluation and recognition of our customers.

Contact us :

Shenzhen AITOP Intelligent Equipment Co. LTD

Sales Manager

Phone/Whatsapp/Wechat:008618520989583/008618435204981

/18098989643/+8618820281861

Email:sales(@)

Packing and shipping

*Be Packed by Wooden Box

*Lead Time: Standard Machine: 7-10 working days after we received your battery pack samples.

*Customized Machine: 15-30 days

Our Service

Pre-sales

1) Inquiry and consulting support. All will be replied in 12 hours.

2) View our Factory and testing the machine, demonstrate how the machine work.

After-Sales

1) Training how to install the machine, training how to use the machine.

2) Engineers available to service machinery overseas

3) 1-year guarantee ( free maintain in a year)

4) Replacement parts and other accessories provided

Looking forward to establish good business relationship with you in the new future,any question,please

Contact us :

Shenzhen AITOP Intelligent Equipment Co. LTD

Sales Manager

Phone/Whatsapp/Wechat:008618520989583/008618435204981

/18098989643/+8618820281861

Email:sales(@)

Contact Supplier

You May Like

New Products

Popular Searches

Recommended Products

Find Similar Products By Category