Guizhou Boda Packing Co., Ltd.

Company Information

Factory direct export, Polypropylene woven bag, block bottom valve bag

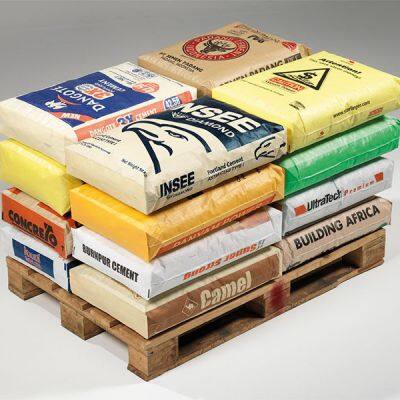

These bags can be used for packing of Cement, Fertilizers, Chemicals & other similar products. Mainly in powdery products.

These PP Woven Valve Bags are accessible in multiple sizes & dimensions that are meet multiple industrial & commercial usage requirements.

Due to unique features of this bag, the material to be packed is filled through filling tube. Block Bottom Bags are perforated with star micro perforation system which allows air to come out holding the cement or other material without allowing any seepage. As soon as the bag is filled the valve shuts automatically providing a self-locking system.

· Production process of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack:

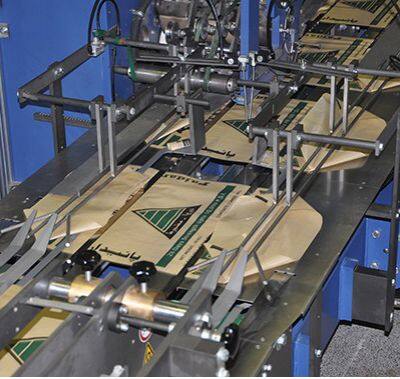

· The following is the whole process to making the Ad*Starkon block bottom valve sack:

· Extruding PP particle---------Drawing and cutting PP film-------thread the PP tapes-------Weaving pp tapes to tubular fabric-------Coated with PE film- offset or flexo Printing the body-------hot air welding the tubular body and bottom and top patches and valve--------Inspecting the strength tensile and air permeability-package

· Advantage of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack:

· Compared with the traditional 3-ply multi-wall paper cement bag and ordinary pp woven plastic bag, the Ad*Starkon block bottom valve sacks have the following advantages:

· 1. Economical- lower sack weight save raw material as against the paper bag and PE bags.

· 2. Cleaner environment - There is no glue adhesive during the whole production process.

· 3. Less risk of damage - high strength tensile pp woven and high speed filling.

· 4. Easy handling-the brick shape box shape is easy to palletizing.

· Quality control of 25kg 50kg kraft paper plastic pp woven composite porland cement bags/sack:

· In order to produce the high quality Ad*Starkon block bottom valve bags, the following is our effort to control quality:

· 1. From material: using 100% original high strength pp material. not recycled or wasted pp material.

· 2. For fabric: control the strength tensile and density of pp tapes to satisfy the loading capacity.

· 3. Inspection: using the machines to test the strength tensile and tearing function after finish the goods.

· 4.Drop test: for safe factor, for each batch of products, will test the air permeability.

Trade & Market

Factory Information

Popular Searches

Recommended Products

- Rice packaging bag vacuum packaging bag

- Transparent printing of white kidney bean coffee packaging bag Shenyang factory wholesale food packaging bag self-supporting zipper bag

- BeiJing Nylon bag resistant food steaming bag/ Vacuum packaging bag

- With aluminum plated film packaging bag Aluminum foil bag

- BeiJing Color printed packaging bag Composite packaging bag

- BeiJingSquare bottom bag, dustproof bag

- paper plastic bags, coated paper bags, oil resistant paper bags

- BeiJingSelf sealing bag/self sealing packaging bag

- BeiJing Laser film heat shrink film packaging trademark

- BeiJing eight sided sealed self sealing zipper bag

- BeiJing Ultra wide and oversized PE film plastic packaging bag, extra wide PE plastic film packaging

- BeiJingВосемь пластиковых пакетов, восемь пластиковых пакетов, восемь плоских пакетов, восемь запечатанных замков, восемь запечатанных молний, восемь запечатанных мешков.

- Пекинский пластиковый пакет (экологический пакет) пластиковая упаковка

- ปักกิ่งถุงบรรจุภัณฑ์พลาสติก (ถุง Eco) บรรจุภัณฑ์พลาสติก

- Vacuum packaging bag,//nylon bag High temperature resistant food steaming bag//Rice vacuum packaging bag

- Aluminum foil bag with aluminum plated film packaging bag

Find Similar Products By Category