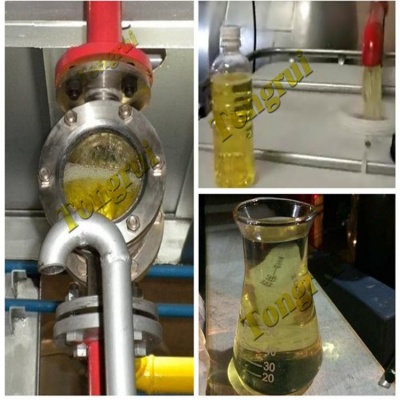

This high vacuum oil purifier performs the function of upgrading and reconditioning of insulating transformer oil by means of removing impurities such as dust,gas,sludge,water etc. The major operation is heating, filtering, degassing and dehydration. After recycling, it can boost performance of transformers, circuit breakers, mutual inductors, cable and capacitors which have insulation system. ZJA series specialize in purifying transformer oil, insulating oil of high voltage and super high voltage transformer. Additionally, it is also suitable for treating low viscosity lubrication oil.

Usages of the Transformer Oil Regeneration Plant:

1.For maintenance of large scale power substation transformers, rapid and deep treatment of new transformer oil, imported insulation oil. As well as vacuum filtering and purifying of mutual inductor oil, capacitor oil, refrigerator oil.

2.Especially suitable for purifying of large scale power transmission units higher than 110KV and transformers of main state grid.

3.It is widely used in power plants, power stations, power companies, metallurgy, petrifaction, machinery, transportation,

railways ect. industries, especially at plateau area higher than 500 meters sea level.

Transformer Oil Regeneration Plant’s Function:

The main function of the ZJA Series of signal and double stage high-efficient vacuum oil purifier is to remove free and dissolved water, gases, and mechanical impurities from insulating oils so as to ensure its purity and improve its insulation property.

It is suitable for the application to oil treatment 500KV super-voltage transforming equipment and 220KV transformers. It is also suitable for the treatment of capacitor oil, transformer oil and freezer oil.

Specification of Transformer Oil Regeneration Machine:

Product Specifications | ||||||||

Item | Unit | ZJA-30 | ZJA-50 | ZJA-75 | ZJA-100 | ZJA-150 | ZJA-200 | ZJA-300 |

Flow rate | L/H | 600 | 1200 | 1800 | 3000 | 4500 | 6000 | 9000 |

Vacuum degree | Pa | ≤133 | ||||||

Ultimate vacuum | Pa | ≤7 | ||||||

Working pressure | Mpa | ≤0.5 | ||||||

Working temperature | ℃ | 30 ~ 60 | ||||||

Power supply | 380V/50Hz (or as per requirement) | |||||||

Noise | dB(A) | ≤78 | ||||||

Heating power | kW | 30 | 45 | 54 | 72 | 120 | 144 | 168 |

Total power | kW | 34 | 49 | 60 | 79 | 131 | 159 | 188 |

Inlet&outlet size | mm | 25 | 32 | 42 | 42 | 50 | 50 | 60 |

Oil index after treatment | ||||||||

Breakdown voltage | KV | 75 | ||||||

Water content | ppm | 3 ~ 5 | ||||||

Gas content | % | ≤0.1 | ||||||

Impurity | µm | 1~5 No free carbon | ||||||

Transformer Oil Regeneration Plant’s Features:

Doubles the evaporation area by adopting Tongrui horizontal double vacuum separation technology efficiently and reliability thorough removal of gas in the oil by using coalescing oil spray separator.

Adoption of American fine filter element, fineness: 5μm, ß≥1000.

Low noise and long life of the oil transport system.

Adoption of American heating technique with the way of thermal radiation, constant temperature control.

The use of a float valve and photoelectric oil level control eliminates supervision.

Adoption of French de-foaming technique to avoid oil leaking.

Controlled digitally and automatically by PLC.

Major electric apparatus are imported from America, so the controlling system safe and reliable.

Optional spare parts:

If you have any questions or needs about double stage vacuum transformer oil purifier, please feel free to contact us.

Facebook

Facebook

X

X

Pinterest

Pinterest

Linkedln

Linkedln