Our industrial turbine oil filtration equipment plays a critical role in maintaining the efficiency and longevity of turbine lubrication systems. It is a versatile solution suitable for a wide range of applications, including steam turbines, gas turbines, and hydraulic turbines in industries such as electric power generation, chemical manufacturing, papermaking, and metallurgy. Our equipment ensures optimal unit performance and the smooth operation of lubrication systems.

Features:

1. Emulsion Breakthrough:

- Utilizes advanced vacuum technology, molecular absorption, and automatic emulsification breaking techniques to completely remove emulsions from oil.

2. Efficient Dehydration:

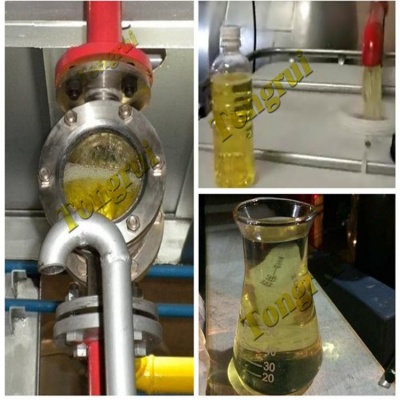

- Employs a unique ternary dehydration method to effectively eliminate both large quantities of water and trace moisture from the oil, ensuring high dehydration efficiency and transforming turbid emulsified oil into clear and transparent fluid.

3. Cost-Effective Operation:

- Designed for long-term use with minimal maintenance costs.

- High-precision filter configuration effectively removes fine particulate impurities from the oil.

4. Enhanced Cooling:

- Combines strong wind and water-cooled technology in a media condensing unit to remove water from high-temperature mixed gas, enhancing equipment performance and lifespan.

5. Uniform Heating:

- Features a low-load heater design that uniformly heats the oil, preventing oil cracking and aging.

6. Advanced Control Systems:

- Equipped with advanced electrical systems and an automatic infrared oil control system for efficient and precise operation.

7. Environmentally Friendly:

- Operates quietly, complying with global environmental protection standards.

- Can run unattended alongside turbines and other equipment.

8. Automatic Drainage:

- Includes an automatic drainage device for continuous drainage, ensuring ease of operation and user-friendliness.

9. Optional Regeneration:

- Offers the option to integrate a BZ regeneration device with the ZJC equipment to reduce oil acidity and dielectric loss. After treatment, the acid value can be reduced to ≤0.03(mgKOH/g), meeting the quality standards outlined in "GB / T 7596-2008" for turbine oil quality. This process demulsifies, dehydrates, removes acid and impurities online, transforming turbid emulsified turbine oil into a clear and transparent state.

Invest in our industrial turbine oil filtration equipment for reliable and efficient lubrication systems, meeting the highest quality standards and environmental requirements.

Facebook

Facebook

X

X

Pinterest

Pinterest

Linkedln

Linkedln