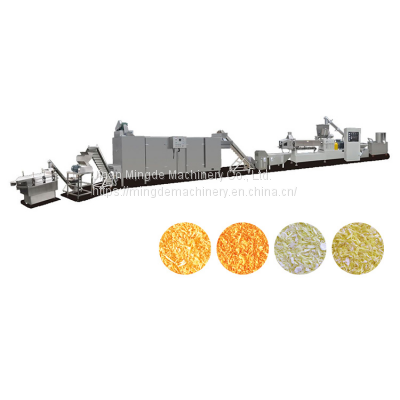

frying food. Strong motivity, Steady running. 2. Screw, barrel, moulds adopt circulating cooling system to keep temperature steady

during working.

3. Raw material is curing and puffed in extruder, becoming different shapes of puffing snacks with moulds

changing.

Facebook

Facebook

X

X

Pinterest

Pinterest

Linkedln

Linkedln