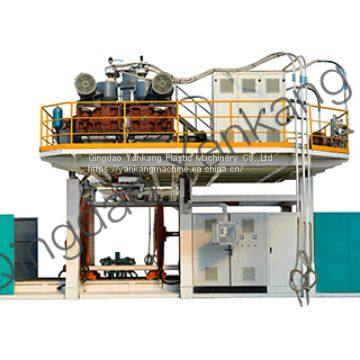

300L Plastic Water Tank Making Machine

The below production information only take 500L machine as an example, detailed information need according to your requirements.

Productivity: 15pcs/h

Delivery Date: 1-2 Month

Blow Moulding Type: Extrusion Blow

Clamping Force: 1800KN

Application: 100L-300L Water Tank/ Water Drum/Water Storage Tank/ Water Barrel

Wall Thickness Controller: MOOG

Control System: SIEMENS PLC Control

Heaters: Introduction Heaters

Motor: Servo Motor

Customization:YES

Automation: Yes

Other Machine: Yes

Visit Factory: Yes

Place of Origin: Shandong, China

Port: Qingdao

Product Display

Technical Advantages

Lastest Technology

1.FOAM LAYER :

Foam layer as a new innovation which can increase the wall thickness.

2.INDUCTION HERTERS:

Induction heaters for die head and extruder can save 40-50% energy.

3.SERVO MOTOR:

Servo motor for clamping system which can save 40% energy.

4.REMOTE SERVICE:

Easier to check machine running conditions, cycle times, output,reminding for machine maintenance. Real-time monitoring is convenient for supplier to check the machine faulty and judge the machine problems.

Service Advantages

Training

The buyer could dispatch their operators to the seller’s factory for training, including machine operation, maintenance & simple repairs.

Or against the requests of the buyer, the seller’s technician could train the buyer’s operators in the buyer’s factory in the periods of installing & adjusting.

Installation & Adjustment

The seller could dispatch an engineer against the requests of the buyer to install and adjust the machines for one week(free of charge) in the buyer’s factory. After one week,if the buyer still needs the training,$100 should be paid for the engineer.

The buyer should make a reservation in advance before delivery of the machines;

The buyer should pay for the engineer’s food & board while installation in buyer’s factory.And the buyer should also pay for the air ticket for the engineer.

After-Sale Service

Guarantee

The guarantee time is one year after the machines normally works in the buyer’s factory, if only the problem is cause due to quality control or any reason by the seller. We will supply replaced parts free of charge and our engineers will guide you how to solve the problems.

Related Products

Water Tank Blow Molding Machine

Plastic Pallet Blow Molding Machine

Road Barrier Blow Molding Machine

Double Ring Drum Blow Molding Machine

IBC Tank Blow Molding Machine

Yankang also provide Blow Molding Machine Molds and Blow Molding Machine Auxiliary Machine.

In order to ensure the quality and accuracy of blow molding molds, the molds are designed and produced independently by our own engineers.

In addition, our engineer will make economical and effective machine plan and choose the suitable auxiliary machine according to customer's requirements.

Blow Molding Machine Molds

Blow Molding Machine Auxiliary Machine

Blow Molding Machine Application

About Us

Yankang was founded in 2009,Located in Qingdao City, China. It is the biggest water tank blow molding machine manufacturers in China, which is specialized in manufacturing, designing in super size blow molding machines and blow moulds with capacity from 200L upto 20,000L for 1-6 layers productions including water storage tank, pallets, road barrier, IBC tank, double ring drum and any other special designs of hollow products.

We have amassed many years of experience in the blow molding industry, strive to advanced blow mold technology, and are always creating new ways to optimize plastic machine performance. Yankang is famous and popular on the machine stable performance, best after sales service and sustainable innovation. As the leading manufacturer of blow molding machines in water tanks,Yankang have set a lot of industrial standards.

More detailed information about related Blow Molding Machine, you can browse our website.

Welcome to contact us if you have any problems at any time.

Facebook

Facebook

X

X

Pinterest

Pinterest

Linkedln

Linkedln