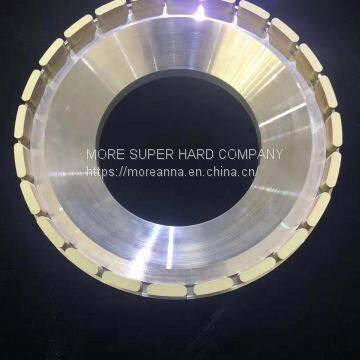

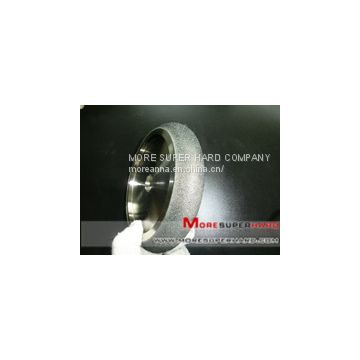

Hybrid wheels ensure higher material removal without compromising on the surface finish, while ensuring considerable reduction in cycle times. These wheels can be used for both Fresh tool manufacturing and re-sharpening, on CNC Tool and Cutter Grinders.

Hybrid wheels can provide below benefits:

Extremely high stock removal rates

Maximum cutting ability

Easy dressing

Higher productivity

Shorter process time during flute grinding

Low grinding forces

High process stability

Quiet and even grinding process

Best tool quality

Hybrid diamond and CBN wheels are used for Fluting, Clearance & Gashing grinding operations.

Our Fluting wheels have shown excellent grinding performance in flute grinding with high stock removal capacity (almost 4mm to 6mm per cutting) combined with a minimum of wheel wear.

These Properties Of The Hybrid Bond Improve The Performance Of The CNC Tool And Cutter Grinder In The Following Ways:

* Increased Rate Of Material Removal With High Temperature Stability

* Reduced Grinding Time Per Component

* Low And Constant Power Consumption

* High Profile Stability And Better Machine Productivity

* Long Wheel Life And Long Dressing Interval.

Applicable CNC Tools Grinding Machine : ANCA,WAlter,SCHUTTE,EWAG,SCHNEEBERGER,HUFFMANN And So On. Have Shown Excellent Grinding Performance Influte Grinding With High Stock Removal Capacity Combined With A Minimum Of Wheel Wear.It Is Not Necessary To Reduce The Infeed Or The Impact Rate With Our Hybrid Diamond/ CBN Grinding Wheel.

The Comparison Between Hybrid Diamond/CBN Grinding Wheel And Usual Grinding Wheel:

If you need any products, do not hesitate to contact

Facebook

Facebook

X

X

Pinterest

Pinterest

Linkedln

Linkedln