Laminated pp woven bag U-panel moistureproof 1 ton bag 1100lbs 2200lbs 3300lbs 4400lbs jumbo FIBC circular type FIBC bag

USD $0.38 - $10.1 /Piece

Min.Order:10 Pieces

Quick Details View All >

Anhui Guanzhong Packaging Co.,Ltd.

Product Details

These bags are tested by independent test institutes in accordance with international quality requirements.

For transportation and storage of hazardous materials, we supplies the UN-class approved FIBC. Which kind of UN bag is appropriate for use depends upon the hazard qualification of the product to be packed. Please be invited to contact us for professional technical advice.

Hygiene requirements has become even more stringent in the field of food and pharmaceutical industries. So the production environment has to be operated under strict hygiene conditions according to BRC-IOP, AIB, ISO-22000 or equal hygiene management systems.

The food grade big bags are produced in conformity with the European and American Directives that apply to packaging materials to come into contact with foodstuffs.

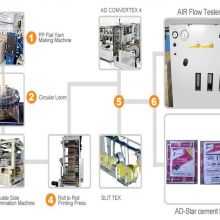

Production Process

● Raw materials polypropylene, we use 100% virgin material which 50% imported from abroad and balance purchased from China’s Sinopec.

● Draw bench yarn, which are subjected to strength and quality tests are wound directly to the

weaving loom Machine.

● The fabric weaved on according to customer’s require and weaved out circular shape or divided into one layer flat fabric. This depends on the style of the big bag ( U panel or Circular or 4 panel)

● The fabric lamination, Our lamination machine can do maximum 250cm width fabric and up to 40gsm one or 2 side lamination. We can also provide BOPP lamination.

● QA & QC for weaving fabric and Yarn testing.

● Bag sewing: After lamination and cut into suitable size of woven fabric, the fabric transferred to the sewing department for sewing. The bag sewing strictly under the technique sheet of the sample confirmed before mass production.

● Inspection: After sewing, the bags will do quality inspection piece by piece and then Dust -proof treatment to make sure the bags clean with good quality.

● The prepared bags are packaged on bales or pallets according to the demands of customers and

ready to delivery.

● Shipping and delivery: For Sample orders, it normally ship by Express or by Air as it’s fastest way to collect and the freight will be higher. And shipment by sea and by train (Truck) are both available. It’s according to client’s require. We can provide any type of Certificate of Origin.

Circular big bag also known as tubular big bag, it is another style of according to the construction division compared to U-panel or 4-panel bag. This tubular shape fabric stands for the bag body, and only need sewing the top panel and bottom panel to form a standard circular big bag.

CONTACT US:

Mr.Daniel

Mobile Phone:+86-13802155833

WeChat:+86-13802155833

WhatsApp:+86-13802155833

Telegram:+86-13802155833

E-mail: tjwoking@163.com

ppwovenbagpacksack@gmail.com

Dimension: | 36’’x36’’x49’’ | Model item | Tubular or Circular |

Material: | 100% New PP material | Color: | White or Beige |

Warp Denier | 1530 D | Woof Denier | 1440 D |

Top Option: | Duffle skirt or filling spout | Bottom Option: | Flat or Discharge spout |

Break Strength | 0.45N/Tex | Usage: | Polypropylene Esters packaging |

Fabric weight: | 180gsm | Fabric Density | 52x56 (pick/100mm) |

Loop Option: | Cross corner, 7cm / 50g/m | Loop Strength | 17500N |

Mononfilament | Warp:65N Woof:78N | Packing: | 190pcs/pallet, 20pallets/20’fcl, 44pallets/40’fcl |

Safety Loading: | 2200 LBS / 1000 KGS | Safety factor: | 3:1, 5:1, 6:1 |

Sewing method | Standard flat sewing | Printing: | 4-side, 8-color available |

Product Specification

Product feature and Application

Our big bags, comply in a wide range of filling, discharging and handling options, customized to fulfill the user’s specific require. With over 15 years of experience in manufacturing bags, our professional staff is available to assist you with any design features.

This style bag will help to keep the bag shape and not enlarge too much after filled with goods. Also, it can prevent powder leakage as there’s no stitches on bag body. The tubular big bag with strength area on bag body for sewing cross corner lifting loops. Various colors can be provided: White, Beige, Black, Green, Blue etc and it refers to user’s specific requirements.

Due to easy using and cost effectiveness, the usage has grown dramatically over the years. Normally these bags are used for packaging powder material such as Flour, Starch, Fertilizer, or Chemical materials.

Production Process

● Pure Raw materials (polypropylene, ultraviolet additives etc.), which have been passed quality control tests and suitable for production, are put in the mixer.

Contact Supplier

You May Like

New Products

Popular Searches

Recommended Products

Find Similar Products By Category