Home > Products > Plastic Thermosetting Mould > BMC Injection Molding Plastic Mold Customization

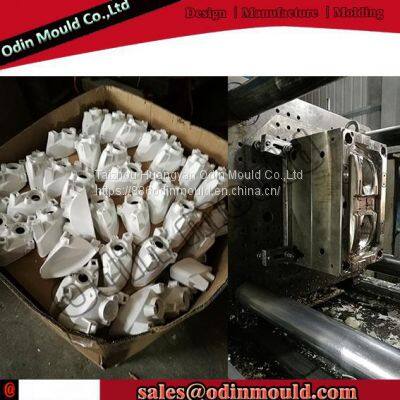

BMC Injection Molding Plastic Mold Customization

- 100 Set / Sets per Month

- Ningbo

- T/T L/C

You May Like

Product Details

| Brand Name: | Odin mould | Place of Origin: | China | Model Number: | Odin-17 |

| Plastic Modling Type: | Mould |

Product Description

BMC Injection Molding Plastic Mold Customization

1. Because the BMC material contains a large amount of glass fiber and filler, it will block the gap between the workpiece and the exhaust groove during molding. Exhaust is equal to discharge, and the exhaust vent should be easy to clean. The place that cannot be cleaned should be designed to take into account the parting surface structure and the cold trough. 2.The resin and filler will block the gap between the workpieces during molding. It is difficult to disassemble after long-term use and cooling. In addition to the thermal expansion of the metal and the accuracy of the product, the matching gap between the workpieces should be fully considered during processing. 3.Because BMC material contains high glass fiber, the flow is poor, the hardness of the material itself is high, and the mold is very worn. When designing, different materials should be considered, and the quenching hardness of the mold material (vacuum heat treatment) HRC50 or above), tempering temperature and surface treatment have high requirements (the mold core is recommended to use Japan's Datong H13 or Sweden 8407) to effectively ensure the use of the mold. 4.The open cavity distribution pattern should be reasonable: the balance of each cavity in a mold is crucial because it is the direct killer of the pass rate. It also affects the appearance of the product. When the balance is not good, the B mode has a problem when the A cavity is satisfied. Conversely, when the B mode satisfies the A mode, the process is difficult to satisfy. 5.BMC materials are very sensitive to temperature. When the temperature difference is large, the product will be deformed, cracked and oversized. Therefore, the mold should be more temperature-detected, and the temperature balance should be fully considered when designing the heating rod. 6.The design of the runner should be as low-pressure and low-speed as possible. The position and angle of the runner should avoid the direct impact on the easily deformable workpiece and the effective discharge of the gas inside the cavity.

|

You can send any of kind above drawing or samples data to us ask quote

Our company can customized plastic parts for customer,possesses advanced Injection Molding Machines,such as 1250T, 780T, 450T, 360T, 250T, 160T, etc in injection molding.

It also comes with one gas-assisted injection equipment, which can produce roof handle products such as hollow.

For mold spare parts, such as springs, thimbles, hot runner accessories, etc., our company will provide customer maintenance and use free of charge.

Order Manufacturing Process

Contact Us

- Taizhou City Huangyan Odin Mould Co.,Ltd

- Contact nameAnna Zhao Chat Now

- Phone86-576-81122133

- AddressHuangyan District Taizhou,Zhejiang

Product Categories

New Products

-

Tpu Injection For Chopping Board

-

Plastic Baby Chair Injection Mould

-

Auto Handle Gas Injection Mold

-

Helmet Injection Mold

-

Plastic Thin Wall Food Container Packaging Box Mould

-

Plastic Flip Top Cap Mould

-

Plastic Injection Large Plant Pot Mould

-

Auto parts car front bumper mold plastic injection mold

-

Plastic Beer Crate Plastic Bottle Crate

-

Mask Melt-blown Cloth Spinneret Die Mould

-

Plastic trash can/bin mold

-

Plastic Bobbin Coil Mold

Popular Searches

Recommended Products

- OEM custom precision CNC plastic injection molding manufacturer nylon abs rubber injection molded service plastic parts

- other rubber product manufacturer,silicone rubber shaped parts,custom EPDM NBR molded rubber parts rubber gasket manufacturing

- abs printing part injection abs plastic molding service parts rubber overmolding plastic 3d silicon injection mold for plastic

- competitive price custom silicone EPDM NBR ffkm molded rubber parts silicone rubber products manufacturer rubber

- abs printing part injection abs plastic molding service parts rubber overmolding plastic 3d silicon injection mold for plastic

- Custom automotive accessories rubber part mould car plastic injection molding service

- OEM Custom ABS Plastic Injection Molding Service Custom Plastic Part Injection Molding Product with Cutting Processing Service

- OEM CNC Machined Custom Plastic Parts ABS PEEK POM Nylon PTFE Micro Machining and Broaching Rapid Prototyping Service

- Professional plastic part injection molding manufacturer custom high quality plastic injection fast molding nylon parts

- China Plastic Products Abs Supplier Custom Medical Device Plastic Products

- Factory Professional Manufacturer Custom Other Plastic Products Plastic Parts Injection Molding

- Factory Professional Manufacturer Custom Other Plastic Products Plastic Parts Injection Molding

Find Similar Products By Category

- Rubber & Plastics > Plastic Products > Automotive Plastic Products