Sintered mesh is made of one or more layers of braided steel wire mesh by a process called "sintering".The single-layer woven wire mesh is the first roller flattened uniformly, to ensure good contact at the wire cross-over points. Then the single layer or more layers of this calendered mesh are then laminated by special fixtures under mechanical pressure in a high-temperature furnace, which is filled with a proprietary embedded gas and the temperature is raised to the point where sintering (diffusion bonding) takes place. After the controlled-cooling process, the mesh has become more rigid, for all the contact points of individual wires bonding to each other. Sintering improves the properties of woven wire mesh through a combination of pressure and heat. Sintered mesh can be a single layer or multiple layers, according to filtration needs, one layer of perforated metal can be added to reinforce the whole structure.

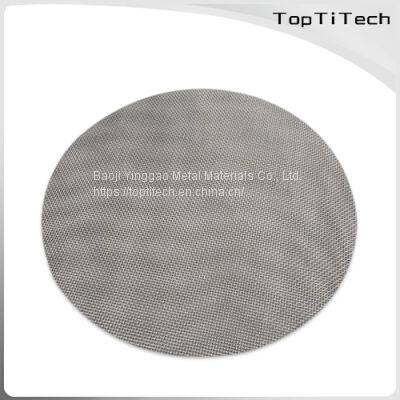

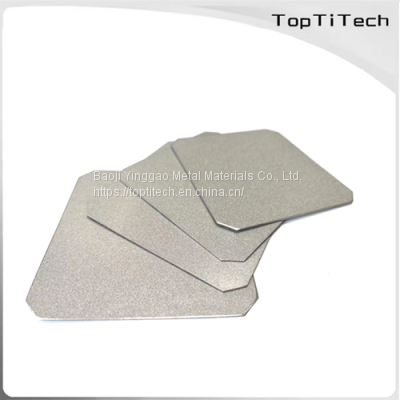

What's more, the sintered mesh can be cut, welded, pleated, and rolled into other shapes, like the disc, plate, cartridge, and cone shape. Compared with traditional wire mesh as a filter, the sintered mesh has prominent advantages, high mechanical strength, high permeability, low-pressure drop, a wide range of filtration ratings, and ease to backwash. Although the cost seems higher than the traditional filter, its long using life and excellent properties gain more popularity with clear advantages.

Why is Sintered Filter needed?

Stainless Steel Sintered Wire Mesh uses several layers of metal mesh sintered together to form a porous metal filter. The fine inner mesh provides accurate filtration within a protective layer. Plate mesh sintering filters are usually used for surface filtration. Solid impurities are trapped on the surface of the control layer, which gives the sintered metal mesh a high filtration accuracy while allowing easy backwashing.

Product Feature

1. Compressive strength and high mechanical strength and compressive strength. Good machining, assembly performance, and welding, simple to use.

2. The filter layer is in the second layer so that it has been well protected and shunt, filtration accuracy can achieve uniform filtration performance, to ensure that it has high stability.

3. 316L material, good corrosion resistance, good heat resistance, can be used for -200℃ ~ 480℃ temperature and acid and alkali environment filtration.

4. Excellent counter-current cleaning effect of the surface filter structure, so counter-current cleaning effect is good, can be used repeatedly, long life. (Can be used counter-current water, filtrate, ultrasonic, melting, baking, and other methods of cleaning).

Facebook

Facebook

X

X

Pinterest

Pinterest

Linkedln

Linkedln