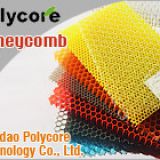

light weight waterproof polypropylene honeycomb FRP sandwich panel

USD $40 - $300 /Piece

Min.Order:50 Pieces

Quick Details View All >

Qingdao Polycore Technology Co.,ltd

light weight stiffness FRP polypropylene honeycomb sandwich panel

light weight stiffness FRP polypropylene honeycomb sandwich panel

light weight stiffness FRP polypropylene honeycomb sandwich panel

light weight stiffness FRP polypropylene honeycomb sandwich panel

light weight stiffness FRP polypropylene honeycomb sandwich panel

Product Details

Fiberglass pre-immerged resin sheet (FRP ) as skin panel on both sides, PP honeycomb as core. Resin adopted is Epoxy or Phenolic .They are composited from high pressure and heating by aero technology. There are about 60% consumption in FRP skin ,so composite panel is more lighter in weight meanwhile more stiffness comparing with cold lamination,in later there are only less than 30% fiberglass adoption in FRP skin.

The features of Polycore FRP PP honeycomb sandwich panel are light weight, high stiffness, sound damping, fire-retardnat, quakeproof, insulation, environmental friendly.

Polycore Honeycomb sandwich panel are applicable to the apartments and external walls of building and truck body, widely Used in boat, yatch, wind turbine, sports, tank cover and so on.

FRP surface thickness from 0.5mm to 3mm made according to clients request. Most commonly application in practice is 1.5mm and 2.0mm.

Uv-treatment, anti-slip surface, gel-coat treatment, painting treatment and so on can be made according to clients request. But because our lamination is heating lamination so Gel-coat or Painting treatment only can be made after composite panel finished so such treatment cost is higher than usually supplier. Considering such cost,we strongly suggest client select original skin or black skin ,the cost is competitive.

Standard specification: 1200*2400mm ,container size:1150*2300mm

Maximal specification: 5500*12000mm.

PP honeycomb sheet thickness from 4mm to 200mm,common in application from 6mm to 40mm. So FRP PP honeycomb composite panel thickness from 7mm to above. Commonly in practice composite panel thickness from 15mm to 40mm.

Sandwich panel is widely applied in Marine as structural material such as hull, deck, bulkhead, tank, canopies and cases; in Tooling as fabricating tooling and moulds; in truck as truck wall, floor,ceiling, fairing, guard; in wind turbine act as blades, canopy housing and rotor hoods; in sport as leisure, film set and decorative market; in corrosion to prevent and repair of metal and concrete surfaces;

in chemical barrier to provide protection for tanks, pits, pipes and grates.

Contact Supplier

You May Like

New Products

Popular Searches

Recommended Products

Find Similar Products By Category