HOT Selling !! WDS 700 iphone ic repair machine with 5 modes easily operation

USD $1 - $3200 /Set

Min.Order:1 Set

Quick Details View All >

Shenzhen Wisdomshow Technology Co.,Led

2019 Economical WDS-700 optical microscope bga welding equipment for iphone 5s samsung note 5

Motherboard repair machine WDS-620 MCGS bga rework station hot selling in Alibaba

Factory price WDS-620 graphic cards repair bga machine with automatic system

WDS-620 bga replacement machine with bga reballing stencil solder ball paser

Hot selling Semi-auto WDS-620 hard disk repair tools with optical alignment

Product Details

HOT Selling !! WDS 700 iphone ic repair machine with 5 modes easily operation

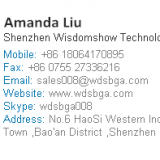

skype: wdsbga008

Whatsapp: +86 18064170895

Main Features:

easy operation , 100% succeess rate

1). Auto soldering ,desoldering and mounting,don't need joystick control.

2). High resolution optical alignment system and HD camera system+3 axies micro adjust, accurate bga position.ensure preci-se mounting .

3). Many different sizes of nozzle, also can be customized .

4).2 temperature zones controlled . the upper hand lower is hot air heating , Could working independent.

5). With a powerful cross-flow and 1 external temp sensor socket.

6).High sensitive touch screen, Panasonic PLC control.

7). Alarm function and double over-temperature protection.

8). CE.ISO9001 approved .

»»» WDS-700 Operation video: https://youtu.be/KZ0kvf6Xkcg

| Item | QTY |

| Total Power | 2500W |

| Upper heating Power | 1200W |

| Lower heating power | 1200W |

| Model Number | WDS-700 rework iphone bga chip |

| Overall Dimension | L450*W470*H670mm |

| Applicable PCB | Max 140*160mm Min 5*5mm |

| Applicable IC | Max 80*80 Min 1*1mm |

| Power Supply | AC220V , 50Hz |

| Weight | 40kg |

| Electric material | High sensitive temperature control module, Delta PLC,Touch screen made in Taiwan |

| Locating Mode | V-shape card slot, PCB holder can be adjustatble X&Y axex with universal jigs |

Detail Show :

Updated system :

Newest WDS-700 is the updated system with 5 modes.It's Remove,Mount,Weld,Manual and Semi-auto.The mode can be changed freely.It can be used under automatic,semi-auto & manual mode. mobile phone repair machine

Independent 2 heating zones temperature control system

1.The upper and lower heating zone,temperature precision control within ±1℃. which can heat up at the same time from the top of he component to the bottom of the PCB;

8 segment temperature control independently. cellphone motherboard repair machine

2.Hot air district heating for BGA and PCB at the same time,the upper or lower temperature

zones could be used alone and combine freely the energy of up and lower heating element.

3. Adopted high precision K-type thermocouple close-loop control and PID parameter self- setting system;

4 .temperature curves can be displayed with instant curve analysis function and multi-group user data can be saved;temperature can be tested precisely through external measurement

interface,curves can be analysed,set and correct on the touch screen at any time.

Precision optical alignment system

Using high definition and adjustable CCD color optical alignment system,beam split,

amplification,lessening,fine adjustment and auto focus with the function that automatic color aberration resolution and brightness adjustment,adjustable image contrast;equipped with 15 ” high definition LCD monitor.

Multi-functional and humanized operation system

1. Adopting the HD touch human-machine interface;upper heating head and mounting head

designed 2 in 1;providing many kinds of titanium alloy BGA tuyere can be rotated in 360 degreefor easy installation and replacement.

2. X,Y and R angle adopted micrometer fine-tuning,accuracy locating,precision can reach

±0.01mm.

Superior safety protection function

With the alarm function, after the BGA welding the machine can alarm by itself.In the case of

temperature abuse, the circuit can power off automatically with the double over-temperature

protection.Temperature parameter having password protection to prevent any modification.

WDS-700 Packing

1. WDS-700 BGA Rework Station * 1 pc

2. Alloy hot gas nozzles * 4 pcs

3. IR High Temperature Sucker * 5 pcs

4. Temperature measurementline * 1 pc

5. Brush * 1 pc

6. Fixture * 6 pcs

7. Plum blossom hander * 6 pcs

8. T nut and screw * 1 set

9. S..creen * 1 pc

10. Nozzle * 1 pser Manual * 1

Pre-Sales Service:

* All productiong lines have adequate quality control and QA/QC inspectors work independently from the production line, All products passed CE & ISO certification.

After-Sales Service:

* Offer free spare parts and service within one year of warranty,but all the other relative cost should be on the buyer's account

* Provide Demo operation video for training ;If you have time,welcome to our company,will arrange engineers to show you the operation.

* Whole-life technological support. 24hours/7 days online .

Why Choose Wisdomshow bga repair machine?

1. R&D Capacity: R&D Engineers in the company. Years of manufacturering experience!

2. Quality Control Management: All production lines have adequate quality control and QA/QC inspectors work independently from the production line!

3. Production Capacity: Annual production capacity: 320,000 sets, 3, 000 square meters factory!

4. On the other side: Srict Supplier Management, Perfect After Sales Service, forein trading employees 24hours/7days serve!

How to get WDS-700 motherboard repairing machine ?

1) This is the first time I use this kind of machine, is it easy to operate?

There is english manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

Contact Supplier

You May Like

New Products

Popular Searches

Recommended Products

Find Similar Products By Category