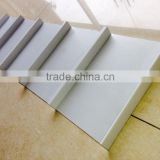

Wire Tube Evaporator for Refrigerator

USD $1.5 - $8 /Piece

Min.Order:100 Pieces

Quick Details View All >

Jingzhou Taijia Refrigeration Equipment Co., Ltd.

Product Details

SPECIFICATION:

1. 30 years professional manufacturing condenser & evaporator experience

2.ROHS,ISO9001.LFGB certificate

3.Good supplier for Midea Refrigerator

4.OEM

CERTIFICATES

Main products | Category |

Wire tube condenser | A.Flat type: 1. 6U/7U/8U/11U/12U/14U wire tube condenser 2. 7rows,21rows,23rows wire tube condenser B. Monolayer flat wire tube condenser C. Double layer flat wire tube condenser D. Winding type wire tube condenser |

Wire tube evaporator | A. Two layer/sheet wire tube condenser B.Three layer wire tube condenser C.Four layer wire tube condenser D.Seven layer wire tube condenser |

Fin Aluminum evaporator /condenser | |

Tube plate evaporator |

PARTS of PRODUCTS

l About us: Taijia--Professional manufacturer for evaporator and condenser

1) Professional factory: Specialized in the production of refrigerator condenser and evaporator in 1984 .We have about 30 years experience in development and practical experience.

2) Technology: It owns over 50 sets of equipment imported from Italy and Switzerland and more than 10 sets of specialized testing and detecting equipment.

3) OEM: operate with Aucma, Little Swan, Midea, LG, TCL and other well-know domestic and foreign enterprises.

4) Advantages: Freon-free, high efficiency and energy saving.

5) Production capacity: Relying on the advanced imported equipment and the unremitting effort of all the staff of the company, the production capacity has reached 3.5 million sets or pieces a year.

COMPANY IMAGES

WORKSHOP

PACKING

description:

Raw material | 1)Rolling welded steel tube : Out Diameter 8mm , Wall Thickness 0.6-0.71mm; |

Structure

| 1) Evaporator for single temperature control system (single capillary evaporator) ; 2) Evaporator for double temperature control system (double capillary evaporator) ; 3) Evaporator for three way temperature control system (three capillary evaporator) ; |

Key Process | Tube bending, Tube welding, Mono shelf assemble, Assembly welding, Leakage testing. Coating, Inspection, Package |

Technical Ability | 1)The distance of steel wire ≥6mm; 2)Produce according to the drawing or sample supplied by clients; |

performance | 1)Surface treated with powder painting or dip coating to prevent the corrosion 2)Inner cleanness can meet the requirement of R134a &CFC cooling system; 3)Can satisfy the cooling capability requirements; 4)Producing Capacity: 3000 piece/Day; |

R134a Cooling System Tube Inside Standards

Residual Moisture | ≤20 mg/m2 |

Residual Impurity | ≤30 mg/m2 |

Residual Mineral Oil | ≤7 mg/m2 |

Residual Chlorine | ≤0.3 mg/m2 |

Residual Paraffin | ≤0.2 mg/m2 |

Specification of Coating

Coating Thickness | Thickness of coating 30-100um |

Harness of Coating | ≥2H |

Impact of Coating | 50 kg/cm impact, no crack |

Adhesion of coating | ≥two grade |

Flexibility of Coating | Around R=3D bend 180, no crack or no fall off |

Color tolerance of Power Painting | E≤1.5 |

We also cooperated with many famous brands and foreign countries. If you are interested in our products,

please don't hesitate to contact us! We can supply products according to your samples or drawings.

Contact Supplier

You May Like

New Products

Find Similar Products By Category