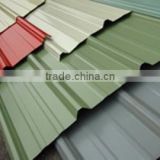

Polycarbonate Corrugated sheet (Ti-Lite ROMA)

USD $5 - $7.5 /Ton

Min.Order:10 Tons

Quick Details View All >

Product Details

Ti-Lite

Exceptional Shading and without Heat

As we know, polycarbonate is the clearest of all plastic resins. How do we add shading properties effectively? Coloring is clearly not the best solution.

At VULCAN Plastics we developed Ti-Lite; integrating TiO2 (Titanium Dioxide) along with other technologies to cope with this issue.

The result is a product with excellent shading properties (46% light transmission rate), and exceptional heat insulation (temperature drop of 7°c~9°c depending on the relative temperature and humidity).

VULCAN Polycarbonate Corrugated Valuview ROMA (76/18) profile sheets are the most sought of product of the VULCAN corrugated sheets family. Used extensively in agricultural greenhouse projects throughout the globe, our Valuview ROMA (76/18) survives the most demanding conditions. Customers can choose between five different material grades to suit your needs*.

Width | Wave Span | Wave Height | Thickness | Production Length | |||

Min. | Max. | Min. | Max. | 20' | 40' | ||

9 Corrugations | 14.5 Corrugations | 76mm | 18mm | 0.6mm | 2.0mm | Max. | Max. |

670mm | 1060mm | 5800mm | 11600mm | ||||

Specifications

Product Strengths

Base Material

UV400 Coating

Ti-Lite Technology

Production Method

High impact resistance

Fire Retardant

Design Flexibility

Quality Standards

VULCAN Polycarbonate sheets are produced with the highest of standards available in the industry. We are the first Polycarbonate manufacture in Asia to incorporate clean rooms for all of our extrusion lines. Our latest Breyer Solid Flat sheet machine is installed in a Class 5000 clean room (the maximum number of particles per cubic foot of air of diameter greater or equal to 0.5 µm is 5000).

Machinery

We have a total of 5 co-extrusion lines, 2 for corrugated sheets and 3 for solid sheets. Our machines are imported from Toshiba-Hitachi Japan, Omipa Italy and Breyer Germany. Our co-extrusion machine uses feedblocks from the industry leading EDI (Extrusion Dies Industries) company and controlled by the also industry leading Dynisco company computers.

Applicable Areas

Agricultural Greenhouse

Garden Greenhouse

Flower Greenhouse

Multi-span Greenhouse

Singe-span Greenhouse

Greenhouse roofing

Greenhouse Walls

Aquaculture Greenhouse

Polycarbonate sound barriers

Polycarbonate Highway barriers

Polycarbonate Skylight

Polycarbonate Warehouse

Polycarbonate Roofing

Warehouse Roofing

Warehouse Skylight

Industrial Skylight

Interior decoration

Car Park

Glazing

Patios

Warehouse

VULCAN Polycarbonate Corrugated Ti-Lite sheet used on our own warehouse.

From the outside:

From the inside: Sufficient lighting with no glare

VULCAN Polycarbonate Corrugated Ti-Lite TRIMDEK sheet uses 100% Virgin resin from Mitsubishi Japan, Bayer Germany, Sabic (GE), and with added TiO2 integration.

All of our sheets are produced using our advanced Co-Extrusion process using EDI (Extrusion Dies Inc.) feedblocks and controlled by Dynisco.

As with all of our polycarbonate products, VULCAN Polycarbonate Corrugated Ti-Lite TRIMDEK uses Optical Grade SD Polyca UV400 resin from Sumitomo Dow Chemicals Japan to protect itself from harmful UV rays.

Impurity leads to less quality, which is why VULCAN Polycarbonate sheets are produced in clean rooms; the cleaner the environment, the cleaner the sheets, and hence a longer lifespan.

Class 5000 Clean Rooms

Optional Plus+ surface treatment provides added light softening properties. (MOQ required)

Other proprietary material from VULCAN Plastics

Contact Supplier

You May Like

New Products

Popular Searches

Recommended Products

Find Similar Products By Category