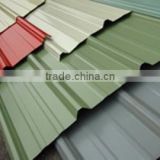

Translucent Polycarbonate Corrugated ROMA sheet ideal for plants(Pearly RED ROMA)

USD $3.67 - $12.22 /Square Meter

Min.Order:6000 Square Meters

Quick Details View All >

Translucent Polycarbonate Corrugated ROMA sheet ideal for greenhouse (Pearly Green ROMA)

Circular Corrugated Greenhouse Polycarbonate Sheet (Valuview Clear ROMA)

Heat reflective IR cut plastic Polycarbonate Corrugated sheet (Pearly RED TRIMDEK)

Co-Extruded Plastic Polycarbonate Corrugated Roofing Sheet (Valuview Blue TRIMDEK)

Co-Extruded Plastic Polycarbonate Corrugated Roofing Sheet (Valuview Green TRIMDEK)

Co-Extruded Plastic Polycarbonate Corrugated Roofing Sheet (Valuview Bronze TRIMDEK)

Product Details

VULCAN PLASTICS

Polycarbonate PEARLY RED ROMA Sheet

Controlled Photosynthetically Active Radiation to stimulate Plant Growth

VULCAN Polycarbonate Corrugated ROMA (76/18) profile sheets are the most sought of product of the

VULCAN corrugated sheets family. Used extensively in agricultural greenhouse projects throughout the globe, our ROMA (76/18) sheet survives the most demanding conditions.

Near RED light make plants grow.

VULCAN PEARLY RED filters out Far Red Light* (735nm) which hinders plant growth and keeps Phytochromes activating near red light (665nm), Plants grow when the phytochromes are exposed to near red light, whereas exposure to far-red light halts the growth process.

* Far red light is at the far end of the visible spectrum, close to the infrared region.

VULCAN Polycarbonate Corrugated and Solid Pearly RED sheets have an eye catching Reddish / Greenish Hue, and is specially designed for plants and vegetation. The special Pearly RED pigment filters out unwanted far Infrared and keeps the near red light which plants need for better growth.

Additional weather Resistant properties ensure a longer lifespan.

Base Material

100% Virgin UV included raw material ensures that your sheets can withstand harmful UV rays for at

least one year.

UV400 Coating

Co-Extruded Bayer Optical Grade UV400 coating as used on lenses, glasses, and sunglasses. 99.5% of

harmful UV wavelengths between 290nm~400nm are blocked.

VULCAN Polycarbonate sheets are produced with the highest of standards available in the industry. We are the first Polycarbonate manufacture in Asia to incorporate clean rooms for all of our extrusion lines. Our latest Breyer Solid Flat sheet machine is installed in a Class 5000 clean room (the maximum number of particles per cubic foot of air of diameter greater or equal to 0.5 µm is 5000).

Co-Extrusion ensures evenly spread, evenly thick base material and UV coating. (A chain is only as strong as it’s weakest link.)

Co-extruded on top of the UV included Base Material, our Optical Grade UV400 master-batch from Bayer Germany and processed by Clariant Swiss, blocks harmful UV rays from 280~400nm. With UV400 coating, VULCAN Polycarbonate sheets are able to last 10 years or more.

We have a total of 5 co-extrusion lines, 2 for corrugated sheets and 3 for solid sheets. Our machines are imported from Toshiba-Hitachi Japan, Omipa Italy and Breyer Germany. Our co-extrusion machine uses feedblocks from the industry leading EDI (Extrusion Dies Industries) company and controlled by the also industry leading Dynisco company computers.

Log onto our Youtube Channel: /user/VULCANPLASTICSTW for a brief tour of our factory.

VULCAN Polycarbonate ROMA profile is one of the most widely used profiles worldwide. Its simple design requires only the most basic structure to install with minimum accessories required.

Agricultural Greenhouse

Garden Greenhouse

Flower Greenhouse

Multi-span Greenhouse

Singe-span Greenhouse

Greenhouse roofing

Greenhouse Walls

Aquaculture Greenhouse

Polycarbonate sound barriers

Polycarbonate Highway barriers

Polycarbonate Skylight

Polycarbonate Warehouse

Polycarbonate Roofing

Warehouse Roofing

Warehouse Skylight

Industrial Skylight

Interior decoration

Car Park

Glazing

Patios

VULCAN Polycarbonate Corrugated PEARLY RED ROMA sheet Greenhouse Project in Kuwait.

VULCAN Polycarbonate Sheets can be made to order and cut to width and length as per customer

request. Any specification of either profile within their respective production range on the Profile Table listed above can be manufactured.

Minimum Order Quantity is for each color/material/profile is approx. 6000 square meters or approx. 5 tons in total weight.

All VULCAN Polycarbonate sheets are co-extruded with Bayer Optical Grade UV400 coating and warranted for 10yrs under normal circumstances*.

*Warranty details are listed on our online Installation Manual .tw/download/VP%20Corrugated%20Sheet%20Installation%20Instructions.pdf, failure to comply shall void warranty.

VULCAN PLASTICS was established in 2007 with the goal of exporting Polycarbonate Sheets of the highest level. With steady progress, we obtained ISO 9001 Certification in the year 2008.

Starting from 1991, we have established a strong foothold in the Polycarbonate Sheet Manufacturing Industry in Taiwan. Following market trends closely and constantly in pursuit of quality and perfection, we continue to develop high-class, multi-functional Polycarbonate Sheets to satisfy customer expectations.

We are now in pursuit of a higher goal, and aim to expand our sales throughout the globe.

Through extensive testing, we have seen what the sun and excessive heat does to a poor product. Vulcan uses only first class, non-recycled material to ensure the lifespan of all our products, which in turn ensures the longlivity of your merchandise.

We are also the first Polycarbonate manufacturer in Asia to incorporate Class 5000 clean rooms for our extrusion lines. (the maximum number of particles per cubic foot of air of diameter greater or equal to 0.5 µm is 5000).

Visit our website .tw for more information about us and our products.

Download our e-catalogue at .tw/download/VULCAN%20Polycarbonate%20Sheets%20Catalogue.PDF

/user/VULCANPLASTICSTW for a brief tour of our factory.

We will be more than happy to assist you in choosing the right VULCAN Polycarbonate sheet for your application.

Contact Supplier

You May Like

New Products

Popular Searches

Recommended Products

Find Similar Products By Category