Product Description

Chocolate Tempering Machine

Our chocolate tempering machine is improved by our company with reference from Italy CM Tempering Casting Machine with more stable working performance and efficiency.

Adopted fully stainless steel wire drawing production,it is totally confirmed with food standard.

Siemens sensor ensure the electric control sensitivity and temperature preserve efficiency, which enable the uniform chocolate tempering.

Compact structure, tempering casting machine is easy to be installed with humanized design and vibration function which makes the chocolate is more beautiful.

Machine introduction:

This chocolate tempering machine can be matched with accessories such as coating, pouring, vibration, etc. to achieve diversified production. It is suitable for chocolate production in various small and medium-sized chocolate factories, chocolate stores, and home workshops.

Main Features:

*Ideal for chocolateries, patisseries, bakers and ice cream parlours. *PLC and HMI controled operation and tempering process.

*Tempers 25 Kg of chocolate in 20 minutes.

*Delta PLC and Schneider electric parts. Chocolate flow rate is adjustable.

*Equipped with pedals, convenient for operation.

*New construction concepts resulting in lower energy consumption. *Quick assemb and disassemb design, easy for cleaning and maintenance.

*Compact size with the option of being equipped with different accessories.

*Accessories available: Depositing plate,vibrating table,enrobing devices, cooling tunnel and more.

*Support remote debugging

Parameter

Mode | GYV-25 | GYV-60 | GYV-100 | GYV-250 |

Capacity | 25L | 60L | 100L | Genyond Continuous Tempering Machine |

Productivity | 80KG/H | 200KG/H | 300KG/H | |

Total Power | 2.5KW | 3.5KW | 5KW | |

Weight | 315KG | 360KG | 450KG | |

Dimension(mm) | 1050*850*1780 | 1350*880*1780 | 1600*900*1100 |

Extra Parts:

Depositing part:

The dosing head distributes the liquid chocolate into the molds. This saves time as the user does not has to scrape the chocolate manually. Furthermore it guarantees hygienic processing.

Depositing part:

The standard version is equipped with two dosing plates (4*6 and 4*8 layout), a mould guidance system installed on the vibrating table, a heated scraper and a dosing unit.

Vibrating table part:

Enrobing part:

Capacity: 1-2m/min Enrobing Belt Size: 200*1000mm Food Grade Belt Size: 200*1900mm Mesh Size: 200*1500mm Food Grade Paper Size:

200mm width Machine Size: 1800*300*1050mm Voltage: Single Phase 220V

200mm width Machine Size: 1800*300*1050mm Voltage: Single Phase 220V

Enrober with double chocolate curtain, vibrating station, adjustable blowing unit, tail cutter, PU conveyor belt .

The thickness of the chocolate can be adjusted by the vibrating system (adjustable intensity) and by the blowing unit . Equiped with roller for food-grade paper.

Conveyor speed adjustable.

Related Products

Usually, chocolate tempering methods include the following steps:

1. Melt the chocolate completely

2. Cooling to the temperature of crystallization

3. Produce crystallization

4. Melt away unstable crystals

Solution temp | Cooling temp | Tempering temp | Cooling temp after depositing | Storage temp | |

Black chocolate | 50~55℃ | 27~28℃ | 31~32℃ | 10~18℃ | 18~20℃ |

Milk chocolate | 45~50℃ | 26~27℃ | 29~30℃ | 10~18℃ | 18~20℃ |

White chocolate | 40~45℃ | 25~26℃ | 28~29℃ | 10~18℃ | 18~20℃ |

Packing & Delivery

Company Profile

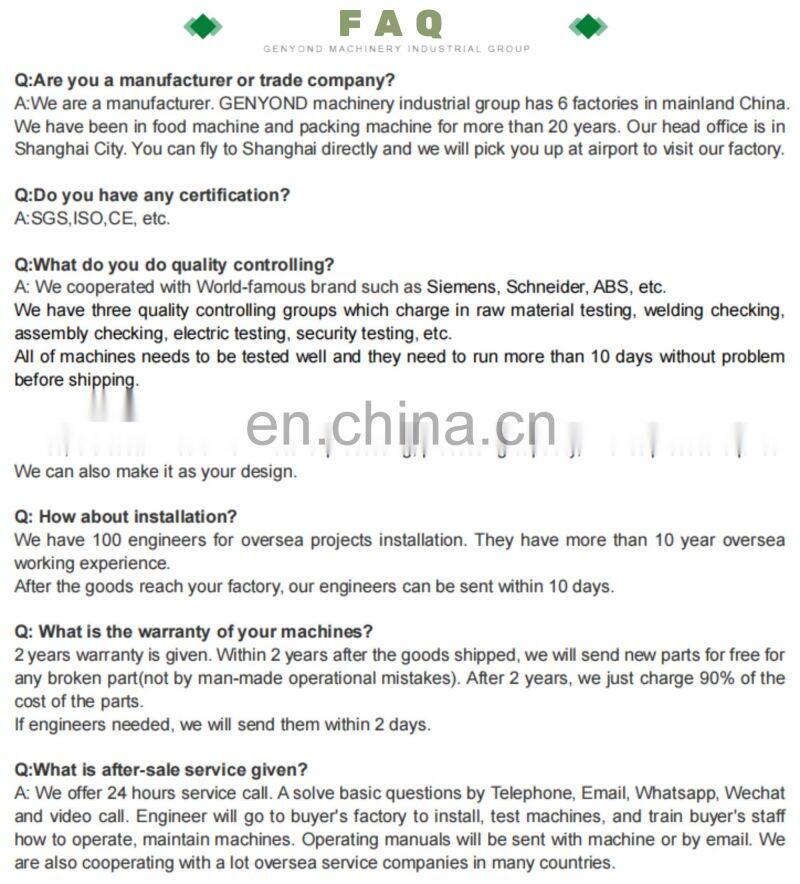

FAQ

Contact Us