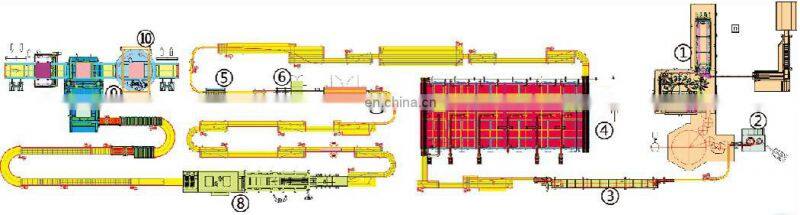

Work flow

System Overview

1. Plant based milk PET bottle aseptic filling line

| 1. Water treatment | 5. Product treatment and homogenization |

| 2. Mixing of meal and water | 6. Flexible heating options |

| 3. Hydrolysis | 7. Aseptic filling |

| 4. Separation of solids and liquids, blending of additives |

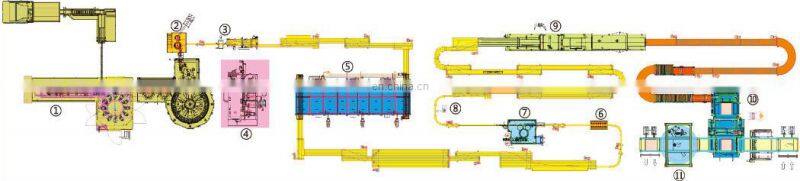

System Overview

Typtical layout drawing and componets 1

| 1. Combi blower/filler/capper | 6. Sleeve labeler |

| 2. Cap feeder / washer | 7. Date coder |

| 3. Cap sterilizer | 8. Carton packer |

| 4. Bottle cooler | 9. Palletizer |

| 5. Dryer | 10. Stretch wrappe |

Typtical layout drawing and componets 2

| 1. Combi blower/filler/capper | 5. Labeler |

| 2. Cap feeder/washer | 6. Date coder |

| 3. FBI | 7. Shrink packer |

| 4. Dryer | 8. Palletizer |

| 9. Stretch wrapper |

Typical layout drawing and componets 3

| 1. Combi blower/filler/capper | 6. Dryer |

| 2. Cap feeder /washer | 7. Labeler |

| 3. FBI | 8. Date coder |

| 4. Mixer | 9. Shrink packer |

| 5. Bottle warmer | 10. Palletizer |

| 11. Stretch wrapper |

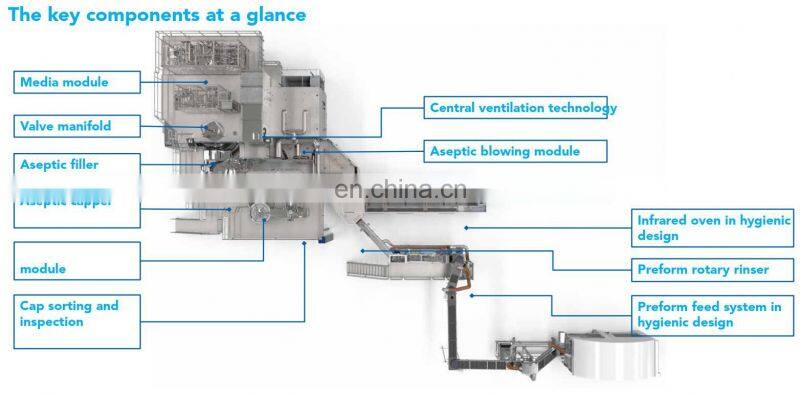

Components overview

| Mainly componets including: | |

| 1. Media module | 7. Central ventilation technology |

| 2. Valve manifold | 8. Aseptic blowing module |

| 3. Aseptic filler | 9. Preform sterilisation module |

| 4. Aseptic capper | 10. Infrared oven in hygienic design |

| 5. Cap sterilisation module | 11. Preform rotary rinser |

| 6. Cap sorting and inspection | 12. Preform feed system in hygienic design |

Specification

| Product model | 3S10A | 6518A |

| Copacity | 15000bph | 27600bph |

| Module parts | sterilize: 1:80, flushing: 55, filling: 35: caping: 10 | sterilize 1:80, sterilize 2:80; flushing:70; filling:65;caping:18 |

| Size | 11650x9250x4500mm | 14460x11750x4500mm |

| Quality | 17200kg | 30700kg |

| Bottle type | 28, 38: 28,38 bottle type interchange: Diameter60-110mm; Helght 150~320mm, Volume: 330~2000ml | |

| Beverage type | Fruit particle Juice, Tea, Soda water, mik, beverage etc | |

| Sterilization | 6D | |

| Inside the bottle sterilization liquid residue | <0.5mg/L | |

| Aseptic period | 72Hours(Depending on the product)no smart clening the middle | |

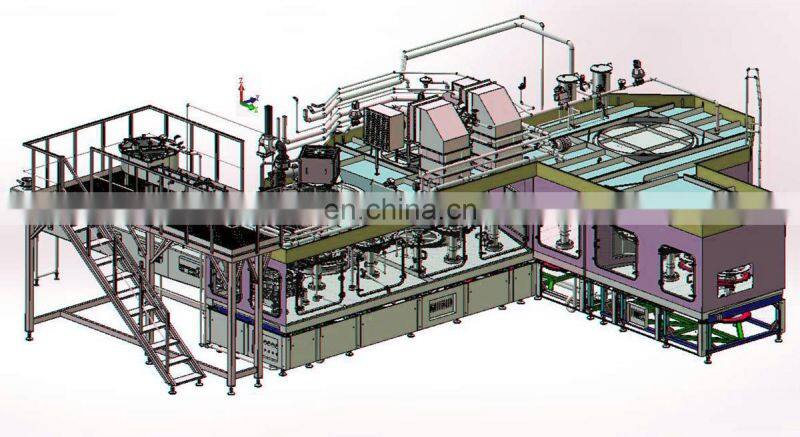

Structure Overview

Model 3S10A:

Model 6518A:

Advantages

| Modular assembly: including aseptci water flushing, filling, rotate capper | |||

|

|

||

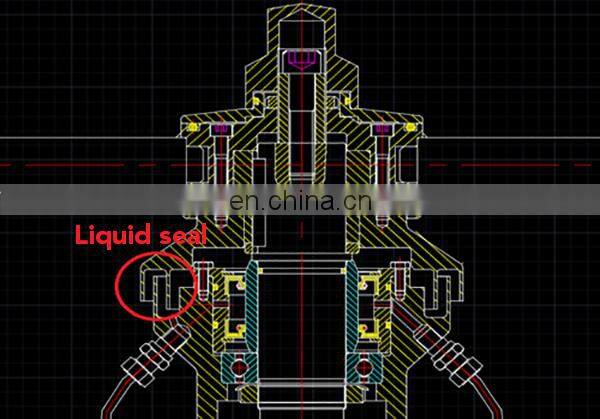

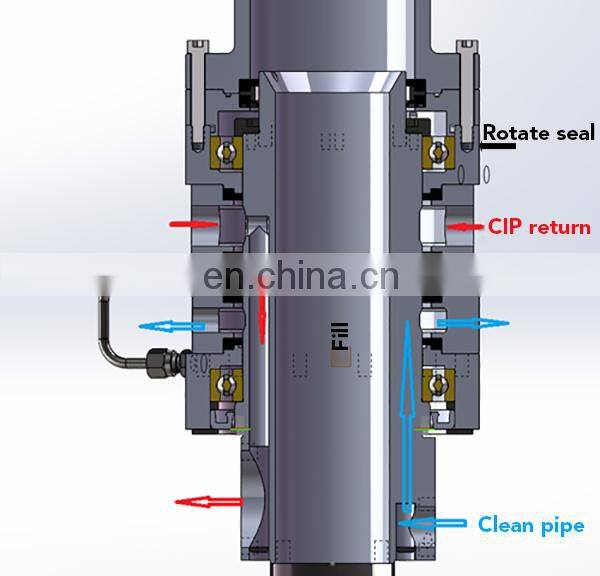

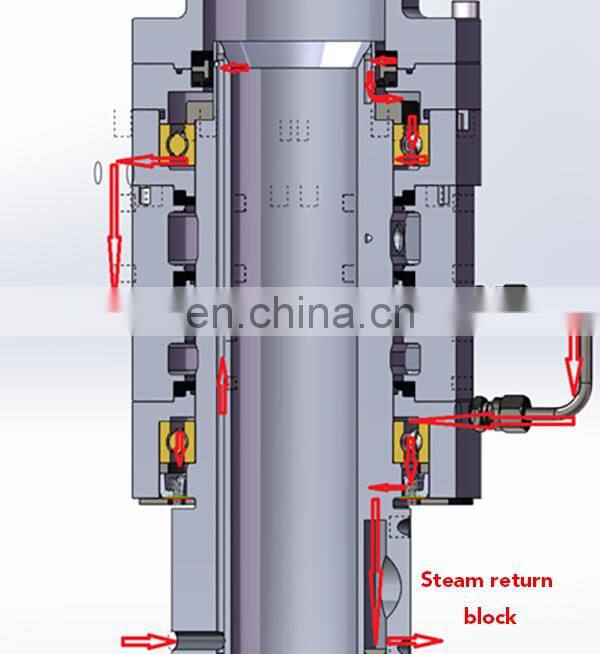

| Hygiene: Aseptic capper is always in a hygienic design and meets even the most difficult hygiene requirements. − All drives are outside the isolator. − A liquid seal system seals all of the capper carrousel's rotational movements. − The movements of the capping head are sealed with bellows. − Depending on the type of cap, a chuck-cone capper or a gripping-head capper are used. |

|||

|

|

||

|

|||

|

|

||

| Most import sterilization

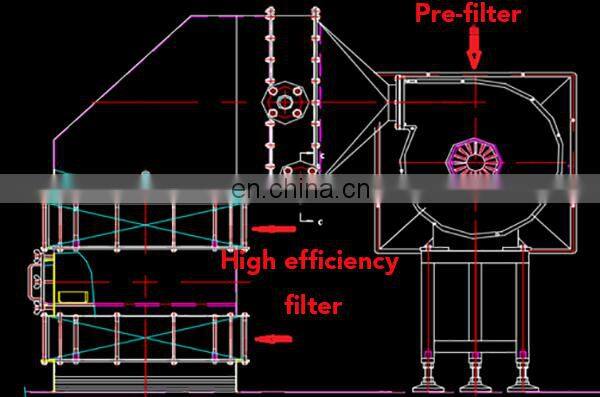

FFU heating and sterilization:

The air supply part of the FFU is equipped with an air heat exchanger, with steam to heat and sterilize the clean air in the filling chamber. It can not only effectively reduce the heating time of the host during sterilization, but also effectively sterilize the high-efficiency filter (dry filter) and extend the service life of the filter. with four layers of filters: The new FFU unit adopts one layer of primary-effect filter, one layer of medium-effect filter, and two layers of high-efficiency filter. |

|||

|

|

||